At present, it is at the critical stage of epidemic prevention and control. While keeping a close guard against the epidemic, all the production lines of SHACMAN have resumed production recently, contributing to the domestic and overseas customers’ needs and stable development of economy.

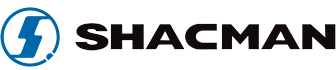

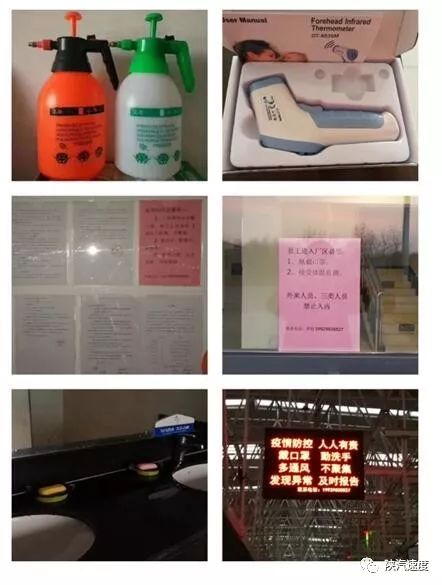

Automobile Assembly Plant

During the epidemic, in order to reduce the concentration of meetings, in the morning of February 13th, the assembly plant held a working meeting outside the staff corridor to grasp the current epidemic prevention and control, production and operation. At the meeting, precise arrangements were made for the recent resumption of work and production: disinfecting the production lines and office areas of the branch in batches; monitor the temperature of employees entering and leaving the workshop and make detailed records; wearing of masks of all staff during the working period.

February 14th, while ensure the physical and mental health of employees, SHACMAN carried out production and resumption of work in an orderly manner.

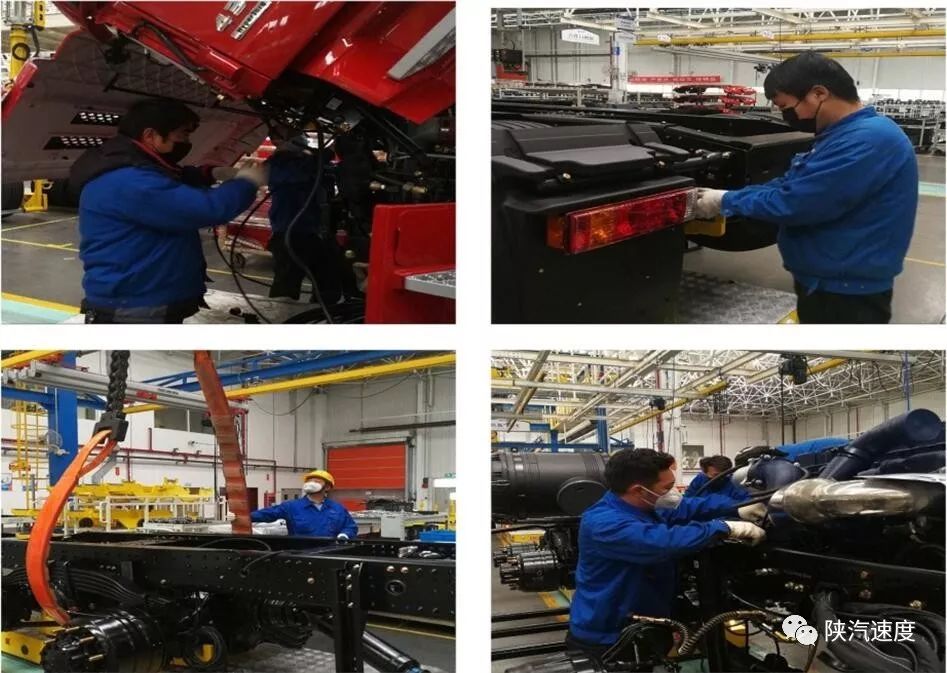

Off Road Vehicle Assembly Plant

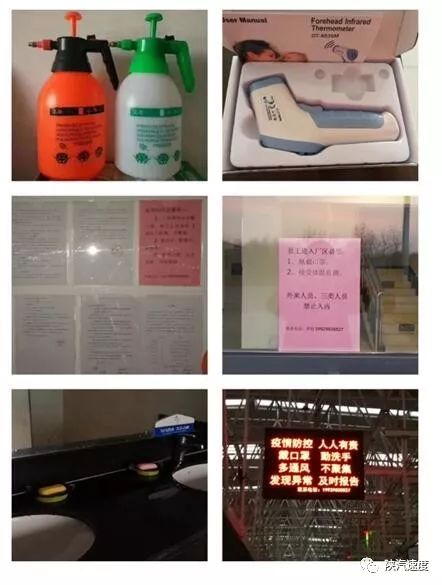

To create a health and safety working environment for staff, to ensure that the epidemic prevention and control production balance and resume work, it is necessary to establish comprehensive commute protection and preventive supplies. Prepare the ‘four lines of defense’ for measuring body temperature and disinfecting environmental equipment before construction starts, and build a ‘copper and iron wall’ for epidemic prevention. On February 14th, with the opening of the four lines of defense, employees successively entered their workplace, and all workshops cooperated with each other. They were busy and shuttered on the u-shaped assembly line, forming a beautiful picture of fighting. In the unity and cooperation of all workshops/departments, the first vehicle got off the line smoothly.

Vehicle body workshop

Recently, under the premise of adhering to the prevention and control of the epidemic situation, the bodywork plant has carried out the resumption of production in a safe and orderly manner in batches. During the special period of epidemic prevention and control, product production must take into account multiple factors such as materials, on-site employees, efficiency, batches, and costs. The daily checks the number of returning employees, positions, material status, and allocates resources in accordance with actual production needs to optimize production plans such as capacity, cost, personnel and materials. The goggles are epidemic materials. In order to provide sufficient supplies, the stamping workshop take the production tasks actively.

Hande Axle

While doing a good job in epidemic prevention and control, Hande Axle established an epidemic prevention and control group to formulate epidemic prevention and control work and emergency plan, comprehensively carry out disinfection work within the factory area, set up health checkpoints in key locations, purchase and store epidemic prevention materials, continuously carry out epidemic prevention and publicity work, set up employee health accounts and resume work. For returning employees, strengthen the prevention of epidemic detection, all units enter the factory in different time periods one by one to take temperature measurement and record work, and always put the health of employees first.

Deshi Group

DESHI Group went to the service site of SHACMAN commercial vehicle and expressed condolences and thanks to the DESHI staff who came to the site as soon as possible after the resumption of work. After checking the production situation of SHACMAN commercial vehicle and the resource guarantee situation of DESHI group during the epidemic period. Arranged and deployed the business work of SHACMAN Commercial Vehicle Departments during the epidemic, and required service personnel to support production at the same time. What’s more, we must prevent and control the epidemic and protect ourselves.

Automobile Assembly Plant

During the epidemic, in order to reduce the concentration of meetings, in the morning of February 13th, the assembly plant held a working meeting outside the staff corridor to grasp the current epidemic prevention and control, production and operation. At the meeting, precise arrangements were made for the recent resumption of work and production: disinfecting the production lines and office areas of the branch in batches; monitor the temperature of employees entering and leaving the workshop and make detailed records; wearing of masks of all staff during the working period.

February 14th, while ensure the physical and mental health of employees, SHACMAN carried out production and resumption of work in an orderly manner.

Off Road Vehicle Assembly Plant

To create a health and safety working environment for staff, to ensure that the epidemic prevention and control production balance and resume work, it is necessary to establish comprehensive commute protection and preventive supplies. Prepare the ‘four lines of defense’ for measuring body temperature and disinfecting environmental equipment before construction starts, and build a ‘copper and iron wall’ for epidemic prevention. On February 14th, with the opening of the four lines of defense, employees successively entered their workplace, and all workshops cooperated with each other. They were busy and shuttered on the u-shaped assembly line, forming a beautiful picture of fighting. In the unity and cooperation of all workshops/departments, the first vehicle got off the line smoothly.

Vehicle body workshop

Recently, under the premise of adhering to the prevention and control of the epidemic situation, the bodywork plant has carried out the resumption of production in a safe and orderly manner in batches. During the special period of epidemic prevention and control, product production must take into account multiple factors such as materials, on-site employees, efficiency, batches, and costs. The daily checks the number of returning employees, positions, material status, and allocates resources in accordance with actual production needs to optimize production plans such as capacity, cost, personnel and materials. The goggles are epidemic materials. In order to provide sufficient supplies, the stamping workshop take the production tasks actively.

Hande Axle

While doing a good job in epidemic prevention and control, Hande Axle established an epidemic prevention and control group to formulate epidemic prevention and control work and emergency plan, comprehensively carry out disinfection work within the factory area, set up health checkpoints in key locations, purchase and store epidemic prevention materials, continuously carry out epidemic prevention and publicity work, set up employee health accounts and resume work. For returning employees, strengthen the prevention of epidemic detection, all units enter the factory in different time periods one by one to take temperature measurement and record work, and always put the health of employees first.

Deshi Group

DESHI Group went to the service site of SHACMAN commercial vehicle and expressed condolences and thanks to the DESHI staff who came to the site as soon as possible after the resumption of work. After checking the production situation of SHACMAN commercial vehicle and the resource guarantee situation of DESHI group during the epidemic period. Arranged and deployed the business work of SHACMAN Commercial Vehicle Departments during the epidemic, and required service personnel to support production at the same time. What’s more, we must prevent and control the epidemic and protect ourselves.